An exciting new venture, aimed at creating opportunities for students to access a construction qualification, is launching.

Our supply chain partner, William King Construction, has worked with West Cumbria Learning Centre and Time To Change (West Cumbria) Project to come up with the Aspire Academy – in the hope that this will have a long term positive impact on the local area.

Having been born and raised in West Cumbria, William King, and Rachel Holliday, from Time to Change, are both very aware of the issues facing the area.

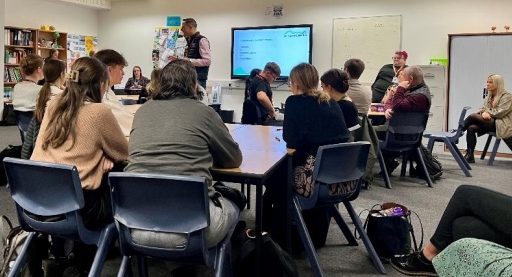

The idea of the Academy was born when they visited West Cumbria Learning Centre to meet children who are excluded from mainstream school.

The headteacher there, Danny Gee, spoke passionately about how so many of his students want to work in construction and how collectively we have the opportunity to ensure that they leave school best placed to access the many and fantastic opportunities locally.

William spoke of the labour skills gap in West Cumbria and all agreed what was needed was a facility which is not strictly a classroom. Instead it is a real life building site where students, in small groups, can grow in confidence and skills, working with mentors in construction and who have faced challenges in their own lives.

Funding for Aspire Academy

Rachel applied for funding, from SPARK (a Sellafield-funded programme for social enterprise), to enable a business plan to be developed. Once this was in place she spoke to local funders and with support from Cumbria Community Foundation, Copeland Community Fund and LLWR, Aspire Academy became a brand new Community Interest Company.

The funding then enabled the space at Westlakes Science Park to be transformed and ready for opening, with assistance from landlords Britain’s Energy Coast (BEC).

The Aspire Academy is set to open its doors to a first intake of six students next week. The youngsters, aged between 14 and 16, will embark on work towards a BTEC course, with William King as their instructor, running one afternoon a week over 10 weeks.

William King, Rachel Holliday and Danny Gee are all Aspire Academy directors and will help to move the project forwards.

William said: “Having come from a West Cumbrian town with low expectations and very few GCSE’s myself, I can relate to some of these pupils through my own experiences during school years.

“I’m hoping to be able to connect with them and share the belief that we can influence some better patterns going forward.

“Success will see students attend Aspire and gain the skills they need to choose their future.

“By evidencing to these students that they can work in construction, there is a bright future for them and we will support them to overcome any barriers they face.

“We would like to see a constant stream of inspired young people leaving their place of schooling and joining the working world with a trade apprenticeship at Lakes College.

“We will be mentoring the children alongside the practical part of the course and giving them extra learning in construction related courses and assisting in things like interview techniques and CV writing.”

Looking to the future

They would like to expand the Academy further in the future to look at adult job seekers, upskilling and also open it up to other schools and adult groups in the area.

Danny added: “We hope to roll this opportunity out to schools who have students who are at risk of exclusion, and for whom a traditional mainstream curriculum does not always engage or meet their needs.

“If we can support students to remain in their mainstream school this would be a benefit all round.”

Morgan Sindall has also stepped forward to offer some construction-based courses to the students, while MKM Building Supplies, at Lillyhall, donated construction materials for the project.

But Will added that they would welcome more support going forward, either financial or offers of tuition help.

He added: “As we open the doors to our students we are looking to sustain the academy through sponsorship of each cohort of students.

“We are open to speaking to supply chain companies who would be willing to offer apprenticeships / work to students who have faced significant challenges in their lives.”

If you can help please contact Rachel by emailing Rachel.holliday@ttcwestcumbria.org

Work has begun on removing the external scaffold which encloses the reinforced concrete box on the Sellafield Product and Residue Store Retreatment Plant (SRP).

Work has begun on removing the external scaffold which encloses the reinforced concrete box on the Sellafield Product and Residue Store Retreatment Plant (SRP).

Manufactured by Hayward Tyler and Stainless Metalcraft, all six pumps were tested with a range of speeds and flowrates at Hayward Tyler, based in Luton.

Manufactured by Hayward Tyler and Stainless Metalcraft, all six pumps were tested with a range of speeds and flowrates at Hayward Tyler, based in Luton.

Mammoet operatives at our Sellafield Product and Residue Store Retreatment Plant (SRP) recently conducted a controlled dummy rescue exercise, using REAX self-descender equipment, to simulate an emergency evacuation from a tower crane.

Mammoet operatives at our Sellafield Product and Residue Store Retreatment Plant (SRP) recently conducted a controlled dummy rescue exercise, using REAX self-descender equipment, to simulate an emergency evacuation from a tower crane. Mammoet operatives regularly carry out rescue demonstrations at least four times per year. After each drill, the team conducts a debrief to assess areas for improvement.

Mammoet operatives regularly carry out rescue demonstrations at least four times per year. After each drill, the team conducts a debrief to assess areas for improvement. A scaffolding supervisor on our Sellafield Product and Residue Store Retreatment Plant (SRP) has talked about his pride in making a difference at PPP.

A scaffolding supervisor on our Sellafield Product and Residue Store Retreatment Plant (SRP) has talked about his pride in making a difference at PPP.

Both were disoriented, with headaches and dizziness, but the alarm’s piercing sound alerted them just in time.

Both were disoriented, with headaches and dizziness, but the alarm’s piercing sound alerted them just in time.